× This is the TEST website for FreemanSupply.com

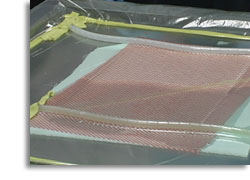

Resin Infusion Epoxy Systems

RenInfusion Epoxy Systems, by Huntsman Advanced Materials, were developed to meet the needs of composites manufacturers involved in vacuum assisted resin transfer molding.

These products feature the low viscosity and long pot life needed for proper wet-out of fiberglass, carbon, and other reinforcing materials used in infusion processes. They also offer good dimensional stability and cured physical characteristics to support production of high quality void-free composite tools and parts.

RenInfusion Epoxy Systems include both one and two-component products developed for use in applications covering a wide range of temperature and performance characteristics.

These products feature the low viscosity and long pot life needed for proper wet-out of fiberglass, carbon, and other reinforcing materials used in infusion processes. They also offer good dimensional stability and cured physical characteristics to support production of high quality void-free composite tools and parts.

RenInfusion Epoxy Systems include both one and two-component products developed for use in applications covering a wide range of temperature and performance characteristics.

Want the details? View the |

Freeman 9602 Epoxy Infusion System New!

Low viscosity, vacuum infusion laminating resin / 70 min. Gel Time / 86D Shore Hardness

Freeman 9604 Epoxy Infusion System New!

Low viscosity, vacuum infusion laminating resin / 130 min. Gel Time / 84D Shore Hardness

Freeman 9605 Epoxy Infusion System New!

Low viscosity, vacuum infusion laminating resin / 8 hr. Gel Time / 89D Shore Hardness

Araldite LY 8601 / Aradur 8602 Epoxy Infusion System

Low viscosity, vacuum infusion laminating resin / 70 min. Gel Time / 82D Shore Hardness

Araldite LY 8604 / Aradur 8604 Epoxy Infusion System

Low viscosity, vacuum infusion laminating resin / 2 hr. Gel Time / 81D Shore Hardness

Araldite LY 8605 / Aradur 8605 Epoxy Infusion System

Low viscosity, vacuum infusion laminating resin / 9 hr. Gel Time / 89D Shore Hardness

RenInfusion 8610 One-Component Epoxy System

One-Component Heat Cure, Low Viscosity, Vacuum Infusion, 89D Shore Hardness